Service Hotline

(82) 010-53271688

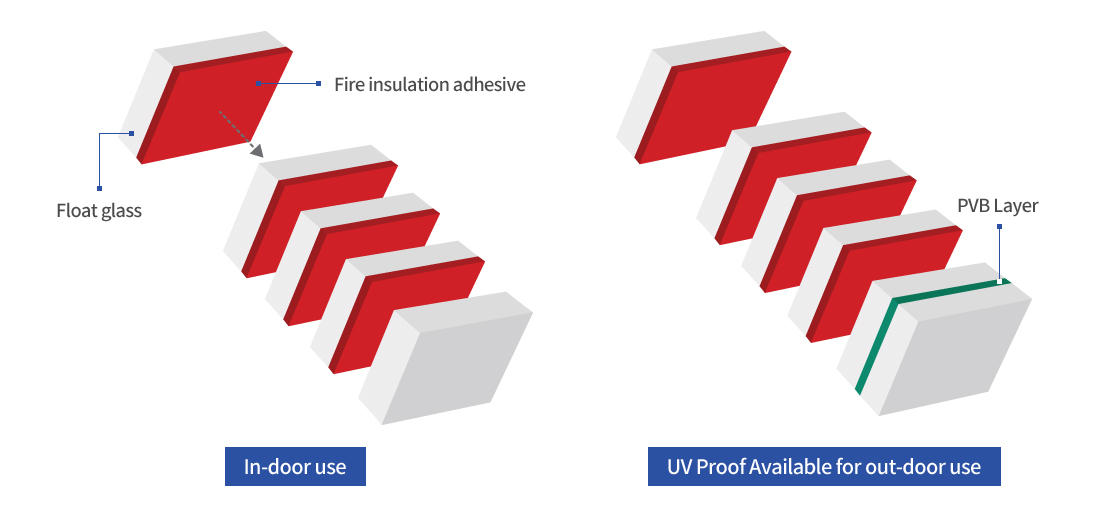

SYP fireproof glass comes in single-pane and laminated glass. The heat-resistant performance of fireproof glass can block flames during a fire accident, helping people prepare for an easy escape. Single-pane fireproof glass is classified as follows according to the Chinese fire resistance test standard. SYP can even produce Class 1 fireproof glass, the highest grade.

Class 1 (≥90 minutes), Class 2 (≥60 minutes), Class 3 (≥45 minutes), Class 4 (≥30 minutes). Single-pane fireproof glass can be made into coated glass, laminated glass, and composite glass.

| Performance | Soda-Lime-Silica Float Glass |

Borosilicate 4.0 Float Glass |

- |

|---|---|---|---|

| Weight per Cubic Meter (Density) | 2500 kg/m³ | 2280 kg/m³ | |

| Hardness (Mohs Hardness) | 5.5 | 6.5 | |

| Vickers Hardness (HV) (200gf ) | 3530 MPa | 4540 MPa | |

| Elasticity (Young's Modulus, E) | 72 GPa | 68 GPa | |

| Poisson's Ratio | 0.22 | 0.20 | |

| Linear Expansion Coefficient (24 - 300°C) | 9.0 × 10⁻⁶ mm/mm·°C | 4.0 × 10⁻⁶ mm/mm·°C | Lower Linear Expansion Coefficient |

| Softening Point T₁ | 715°C | 817°C | |

| Annealing Point | 548°C | 600°C | |

| Strain Point Tg | 511°C | 577°C | |

|

Mechanical Strength of Annealed Glass |

45 MPa | 47 MPa | |

|

Mechanical Strength of Fully Tempered Glass |

120 MPa | 145 MPa | |

|

Thermal Shock Resistance of Annealed Glass |

80°C | 200°C | Better Thermal Shock Resistance |

|

Thermal Shock Resistance of Fully Tempered Glass |

200°C | 350°C | |

| Visible Light Transmittance |

6 mm Transparent Glass: 89% 6 mm Ultra clear glass: 91% |

6 mm: 91.5% | |

| Chemical Stability | Water Resistance: Grade 3 Acid Resistance: Grade 1 Alkali Resistance: Grade 2 |

Water Resistance: Grade 1 Acid Resistance: Grade 1 Alkali Resistance: Grade 2 |

High Borosilicate 4.0 Float Glass is a special glass material with low expansion rate, high temperature resistance, high hardness (scratch resistance), high light transmittance, and high chemical stability. Due to its excellent performance, it is widely used in industries such as building fire protection, solar energy, chemical engineering, electric light sources, and handicrafts.

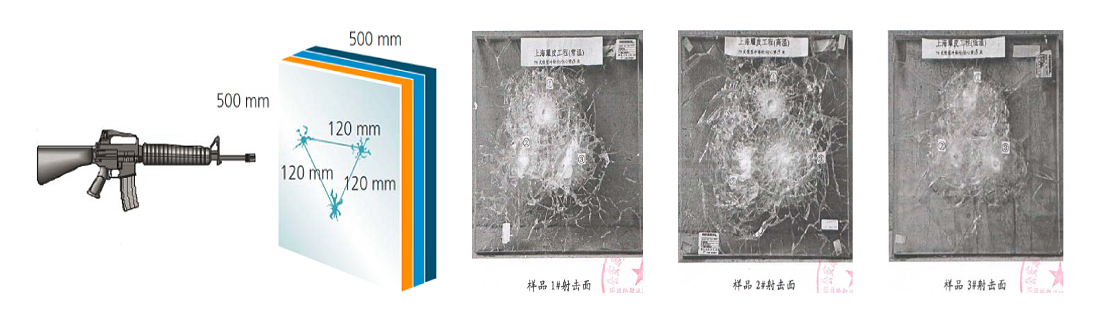

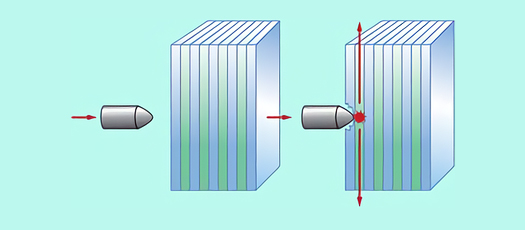

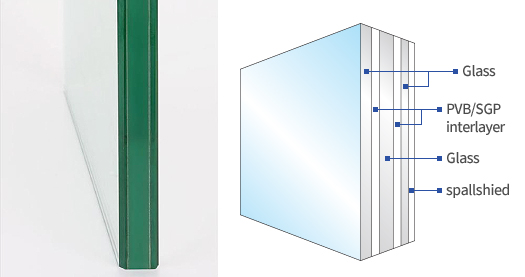

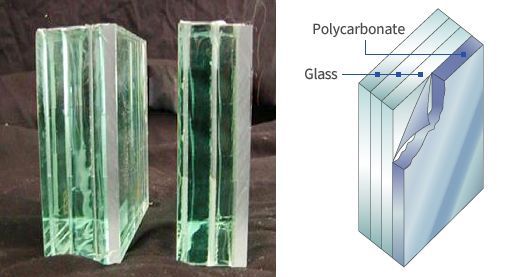

Bulletproof glass is a composite material obtained by specially processing glass and high-quality engineering plastics. Bulletproof glass is a transparent material that looks no different from ordinary glass and can prevent bullets from penetrating, providing certain protection against small arms fire.

| Type | Level | Ammunition (Corresponding Bullet Types) | Thickness (mm) |

Unit Weight (kg/m²) |

Transmittance (LT) |

|---|---|---|---|---|---|

| Traditional Bulletproof Glass | F64 Pistol |

7.62 × 25 mm Steel Core, Copper-Clad Steel |

26 | 61 | 71% |

| Lightweight Bulletproof Glass | 14 | 24 | 84% | ||

| Traditional Bulletproof Glass | F79 Submachine Gun |

7.62 × 25 mm Steel Core, Copper-Clad Steel |

31.5 | 73.5 | 70% |

| Lightweight Bulletproof Glass | 17 | 29 | 83% | ||

| Traditional Bulletproof Glass | F56 Automatic Rifle |

7.62 × 39 mm Steel Core, Lead Sleeve, Copper-Clad Steel |

45 - 50 | 92 | 64% |

| Lightweight Bulletproof Glass | 32 - 34 | 50 | 78% | ||

| Traditional Bulletproof Glass | FJ79 Sniper Rifle |

7.62 × 54 mm Steel Core, Lead Sleeve, Copper-Clad Steel |

Unconfirmed | Unconfirmed | 50% |

| Lightweight Bulletproof Glass | 37 - 40 | 64 | 79% |